Overview:

Wing skin panes are part of the various components of the wing

structure like flaps, aerolons and spar caps. The basic functionality of the

wing skin that it provides a smooth contoured surface which provides lifting

for the aircraft. From its basic name “wing skin” this part is regarded as an

outer layer thin sheet for the wing structure in which its bending deformation

provides the aerofoil shape of the whole wing. Wing types, theory and

loading will be discussed in details.

Wing

types

Aircraft can be

categorized by their configurations. One measure is the number of wings, and

the styles include monoplanes, with a single wing (that is, on either side of the

fuselage); biplanes, with two wings, one atop the other; and even, though

rarely, triplanes and quadplanes. A tandem-wing craft has two wings, one placed forward of the other.

The wing planform is the shape it forms when

seen from above. Delta wings are formed in the shape of the Greek letter delta (D)

and are triangular wings lying at roughly a right angle to the fuselage. The

supersonic Concorde features delta wings.

Swept wings are

angled, usually to the rear and often at an angle of about 35°. Forward swept

wings also are used on some research craft.

Some aircraft have wings that may be adjusted

in flight to attach at various angles to the fuselage; these are called variable incidence wings. Variable geometry (swing) wings can vary the sweep (i.e.,

the angle of a wing with respect to the plane perpendicular to the longitudinal

axis of the craft) of their wings in flight. These two types have primarily

military applications, as does the oblique wing, in which the wing is attached at an angle of about 60°

as an alternative to the standard symmetrical wing sweep.

Another configuration limited to

military craft is the so-called flying wing, a tailless craft having all its elements encompassed

within the wing structure (as in the Northrop B-2 bomber). Unlike the flying

wing, the lifting-body aircraft (such as the U.S. space shuttle) generates lift

in part or totally by the shape of the fuselage rather than the wing, which is

severely reduced in size or altogether absent.

Another configuration limited to

military craft is the so-called flying wing, a tailless craft having all its elements encompassed

within the wing structure (as in the Northrop B-2 bomber). Unlike the flying

wing, the lifting-body aircraft (such as the U.S. space shuttle) generates lift

in part or totally by the shape of the fuselage rather than the wing, which is

severely reduced in size or altogether absent.

Wing theory:

Wing theory:

The type of operation for which an airplane

is intended has a very important bearing on the selection of the shape and

design of the wing for that airplane. If the airplane is designed for low

speed, a thick airfoil is most efficient. A thin airfoil is best for high

speed.

CONVENTIONAL AIRFOILS and LAMINAR FLOW

AIRFOILS , are in common use in

airplane design.

Laminar flow airfoils were originally

developed for the purpose of making an airplane fly faster. The laminar flow

wing is usually thinner than the conventional airfoil, the leading edge is more

pointed and its upper and lower surfaces are nearly symmetrical. The major and

most important difference between the two types of airfoil is this, the thickest

part of a laminar wing occurs at 50% chord while in the conventional design the

thickest part is at 25% chord.

The effect achieved by this type of design of

a wing is to maintain the laminar flow of air throughout a greater percentage

of the chord of the wing and to control the transition point. Drag is therefore

considerably reduced since the laminar airfoil takes less energy to slide

through the air. The pressure distribution on the laminar flow wing is much

more even since the camber of the wing from the leading edge to the point of

maximum camber is more gradual than on the conventional airfoil. However, at

the point of stall, the transition point moves more rapidly forward.

The type of operation for which an airplane

is intended has a very important bearing on the selection of the shape and

design of the wing for that airplane. Boundary layer effects play a very

important part in determining the drag for the aircraft. Thus, the wing

should be designed to minimize the drag.

THE BOUNDARY LAYER

The boundary layer is a very thin layer of

air lying over the surface of the wing (and, for that matter, all other surfaces

of the airplane). Because air has viscosity, this layer of air tends to adhere

to the wing. As the wing moves forward through the air, the boundary layer at

first flows smoothly over the streamlined shape of the airfoil. Here the flow

is called the laminar layer.

As the boundary layer approaches the center

of the wing, it begins to lose speed due to skin friction and it becomes

thicker and turbulent. Here it is called the turbulent layer. The point

at which the boundary layer changes from laminar to turbulent is called the

transition point (Fig. 3). Where the boundary layer becomes turbulent, drag due

to skin friction is relatively high. As speed increases, the transition point

tends to move forward. As the angle of attack increases, the transition point

also tends to move forward.

Fig. 3

Various methods have been developed to

control the boundary layer in order to reduce skin friction drag.

Suction Method. One method uses a series of thin slots in the wing

running out from the wing root towards the tip. A vacuum sucks the air down

through the slots, preventing the airflow from breaking away from the wing and

forcing it to follow the curvature of the wing surface. The air, which is

sucked in, siphons through the ducts inside the wing and is exhausted backwards

to provide a little extra thrust. The laminar flow airfoil is itself a

structural design intended to make possible better boundary layer control. The

thickest part of a laminar flow wing occurs at 50% chord. The transition point

at which the laminar flow of air breaks down into turbulence is at or near the

thickest part. The transition point at which the laminar flow of air becomes

turbulent on a laminar flow airfoil is rearward of that same point on a

conventional designed airfoil.

Vortex generators are small plates about an inch deep standing on edge

in a row spanwise along the wing. They are placed at an angle of attack and

(like a wing airfoil section) generate vortices. These tend to prevent or delay

the breakaway of the boundary layer by re-energizing it. They are lighter and

simpler than the suction boundary layer control system described above.

Airfoils and the production of lift:

Air weighs about .0078lbs/cu. ft. This means

that many cubic feet of air must pass over the wing to create sufficient lift

to carry the all up weight (AUW) of the aircraft. Conventional thick airfoils

have a thickness ratio to the wing chord of 15% to 18%. This thick airfoil

creates a high lift, slow flying wing. It is suitable for a low horsepower,

land based aircraft. This type of airfoil is also used with amphibious aircraft

that need a lot of horsepower and lift to break free from the water.

Medium thick airfoils are about 12% thickness

ratio to the wing chord. These airfoils do not create as much lift at slow

speeds and need to move faster through the air to carry a similar load as the

thicker airfoil sections. The 12% airfoil also stalls at higher speeds than the

thicker airfoil. Aircraft with a 12% airfoil fly faster and often use more

horsepower when used in aerobatic type aircraft. This type of airfoil section

is mainly used on conventional land based sport aircraft.

A low profile airfoil section of 8% thickness

ratio to wing chord is called a Laminar Flow Airfoil and is used for

high-performance, high speed, and some touring aircraft. Laminar flow airfoil

sections have a high stall speed and require a perfect smooth leading edge to

produce the lift required to make the aircraft fly.

Any contamination on the leading edge of the

wing by bugs, irregularities, or indentations by airborne particles will

destroy the lift capabilities of the airfoil. Under these circumstances, it is

guaranteed that the wing will become ineffective and the aircraft will stall.

Aircraft with this type of airfoil are not

recommended for low time and recreational pilots. However, some modern

designers are trying to address this problem. They are designing

user-friendlier laminar flow airfoils. An example would be the Europa Aircraft

Company in Britain.

Thick airfoil sections have strong deep spars

that allow for long wing panels. Example: The Coot Amphibian has a 15%

thickness to chord and a wingspan of 36 ft. Thin airfoil sections do not have

deep spars. They tend to have short wing panels due to structural problems with

long, thin spars. Example: The Cassutt Racer with a wingspan of 15 ft.

Wing load:

This is the ratio of all up weight to wing

area. (AUW to WA.) For conventional aircraft, the calculations are as follows.

With less than 6lbs per square foot the aircraft tends to float down the runway

when landing. This means that the wing generates a lot of lift and counteracts

the gravitational pull of the AUW of the aircraft. This type of aircraft

usually has a big wing area in relationship to the AUW. This light aircraft

design is said to be "light." A light aircraft design with a wing

load over 15lbs per square foot is said to be "heavy."

Heavy aircraft will stall sooner and do not

float down the runway on landing. Example: A Boeing 747 fully loaded to its

design limits may weigh 380 tons at take off. After burning up 150 tons of fuel

on its journey, the aircraft may only weigh 230 tons and its wing load is so

light, it will float down the runway like a glider.

Single seat light aircraft designs are about

8lbs to 10lbs per square foot. Two seat light aircraft designs are somewhere

between 12lbs to 15lbs per square foot. A 2-seat amphibian should have a wing

load of about 10lbs to 12lbs/sq. ft. The stall speed of an aircraft is the

minimum flight, or crash speed. Aircraft stall speed is directly related to the

aircraft wing load. Low wing load = low stall speed. High wing load = high

stall speed. An aircraft with no flaps and a low wing load of about 8lbs/sq.

ft. stalls at about 48mph. An aircraft with a high wing load of about 15lbs/sq.

ft. will stall well over 70mph. The landing speed may be reduced by about 5mph

due to ground effect.

Composites are ideal for applications where

high stiffness and low weight are required. A classic example of such a product

is an airplane wing. In this week's feature, we'll take a detailed look at a

typical composite wing design.

Terminology

|

|

|

Typical Wing Section |

The curved edge on

the left is called the leading edge; it is the forward edge of the wing.

The pointed edge on the right is called the trailing edge. The distance

from the leading edge to the trailing edge is called the chord. This

sample has a chord length of 18 inches. A full wing may have a constant or a

varying chord.

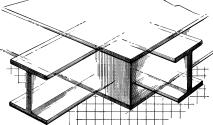

The two vertical

members are the spars. The one closest to the leading edge is the forward

spar; the one closest to the trailing edge is the aft spar. The

forward spar is actually an I-beam--the vertical piece is the spar web

and the thick graphite plates at top and bottom are the spar caps. The

spar carries most of the bending load in the wing.

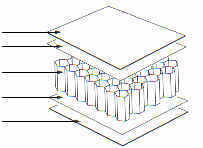

Wing Design

The wing is made in several parts. The upper

and lower skins are layed up separately in female tools (the outer sides are

placed against the tool face). Nomex honeycomb is used to increase the bending

stiffness of the skins.

|

|

|

Forward Spar |

The spars are layed up on a flat table; the

web and caps of the forward spar are layed up separately. Both webs have a

Nomex honeycomb core, but a real wing might have local reinforcements of solid

graphite or some other material for point loadings.

To assemble the wing, the spar caps are

bonded to the upper and lower skins. The high loads carried through the spar

could cause the honeycomb to fail, so the skin core must be tapered at the

spars. This wing uses a 30 degree taper, which is typical for most structures.

Larger angles would create a high stress concentration at the taper; smaller

angles would be difficult to manufacture.

Next, the webs are then bonded to the lower

skin or spar cap (it could just as easily be the upper). A relatively thick

layer of adhesive goes between the web and skin, and then one or two plies of

graphite are layed up over both the web and skin to provide better load

transfer. These latter plies form an "L" shape, and are sometimes

called angle plies.

|

|

|

Leading Edge |

Once the spars are in place, the upper skin

can be bonded in place. The spar bonds on the upper skin are similar to the

lower skin (the actual process is rather tricky, because you don't have access

to the inside on a full wing).

The leading edge bond is a simple lap joint.

The honeycomb on both the upper and lower skins tapers at the leading edge--the

curvature of the wing provides enough stiffness here. The upper skin curves

around well onto the lower skin (the red line of adhesive shows the end of the

upper skin). The lower skin curves roughly halfway up the sharp bend of the

leading edge. Because the lower skin goes on the outside, the upper skin must

have a slight step (equal to the thickness of the lower skin) to keep the

leading edge smooth.

|

|

|

Trailing Edge |

The trailing edge bond looks simpler, but it

is actually more difficult. Because it comes to a point, the skins can't wrap

around each other. Instead, a thick adhesive paste layer is placed on the lower

skin and the upper skin is pressed into this layer. Ideally, the honeycomb

would be continued all the way to the edge, but it must be tapered earlier to

fit the skins together.

The wing is finished by priming and painting.

In this case, standard automotive paint is used. Some paint has been left off

the trailing edge to show the original surface. The thin gray band is the

primer coat.

This sample is typical of a composite wing,

but it is not identical to any existing wing designs. In particular, the forward

spar caps are much thicker than they need to be for a wing this size. Also,

this wing section lacks any control surfaces such as ailerons.

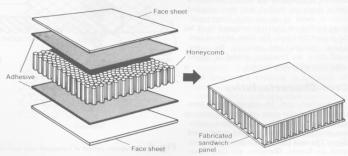

Core

Materials for Sandwich Structures

Bonded sandwich

structures have been a basic component of the composites industry

for over 45 years. The concept of using relatively thin, strong face sheets

bonded to thicker, lightweight core materials has allowed the industry to build

strong, stiff, light and highly durable structures that otherwise would not be

practical. This technology has been demonstrated in boats, trucks, and building

panels. A 3% weight increase can increase the flexural strength and stiffness

by a magnitude of 3.5 times and 7 times respectively if cores and skins are

properly chosen. The structure then acts more or less monolithically.

The most common comparison made is that of a composite sandwich to an

I-beam. The panel skins, like the flanges of the I-beam, carry the stresses imposed

by use. The stresses are transferred between the top and bottom skins through

shear stresses that run through the core or web of the I-beam. The purpose of

an I-beam is to lessen the weight required to support a given load in bending.

Since the highest stresses are carried at the extremities, both the top and

bottom of the I-beam, the center section can be much narrower in width in

relation to the flanges. In a sandwich structure, the core will generally have

the same width and length dimensions as the skins, but can be much weaker than

the skins since it primarily experiences shear stresses. Care must be taken in

design to ensure that the shear carrying capability of the expected loads does

not exceed both the core and the adhesive.

Face sheets can be

of almost any material. In the composites industry, the most common face sheets

are glass and carbon. The common core materials are foam, syntactic foam, honeycomb, and balsa wood. Some core materials can be shaped, such as a

waffle pattern or corrugation to achieve the desired mechanical properties.

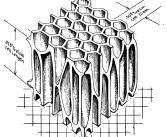

Honeycomb

Sandwich Construction

Honeycomb

Sandwich Construction

A cost-effective and superior sandwich construction uses end-grain balsa

wood. This material has exceptional bond, high impact and fatigue resistance

with excellent strength/stiffness and lightweight properties. Balsa wood is

“mother nature’s” honeycomb material. Balsa has a high-aspect ratio and

directionally aligned cells such that the grain is oriented in the direction of

the maximum stress. Balsa has a proven track record in products such as

pleasure boat hulls, military aircraft, vehicles, and corrosion-resistant

industrial tanks.

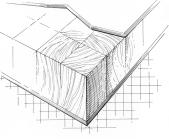

Laminated

Sandwich Construction with Balsa Wood

Laminated

Sandwich Construction with Balsa Wood

The

first composite material to be used widely for ground transportation was

honeycomb, a lightweight structurally stiffening material. Today, honeycomb can

be metallic (Aluminum) or non-metallic (Aramid, Glass, Paper), and when

sandwiched between facing skins it forms an exceptionally lightweight but stiff

construction.

It is easy to see why honeycomb was quickly adopted for ground transportation.

It requires no special equipment or handling, and can be cut and shaped using

simple woodworking tools. It is also considered as a non-combustible material,

meeting today’s fire, smoke and toxicity (FST) regulations.

Aluminum honeycomb possesses remarkable kinetic energy absorbing properties.

The honeycomb crushes under load in a uniform way, preventing damage to the

supporting structure. Being virtually free of rebound and lighter than

alternative materials, aluminum honeycomb is one of the most reliable efficient

and practical energy absorbing materials available.In the rail industry,

aluminum honeycomb is the ideal materials for buffers, fenders and driver

protection. Hexcel supplies energy absorbers to the JT42 (Alstom, Spain), Loco

2000 (SLM and BLS, Switzerland), Pendolino (Alstom Spain and Fiat Ferroviaria,

Italy), TGV Korea (Alstom, France) and BB36000 (Alstom, France) projects.

Wing construction and loading:

The particular wing design depends upon many

factors for example, size, weight, use of the aircraft, desired landing speed,

and desired rate of climb. In some aircraft, the larger compartments of the

wings are used as fuel tanks. The wings are designated as right and left,

corresponding to the right- and left-hand sides of a pilot seated in the

aircraft.

The wing structures of most naval aircraft

are of an all-metal construction, usually of the cantilever design; that is, no

external bracing is required. Usually wings are of the stress-skin type. This

means that the skin is part of the basic wing structure and carries part of the

loads and stresses. The internal structure is made of "spars and

stringers" running spanwise, and "ribs and formers" running

coordwise (leading edge to trailing edge). The spars are the main structural

members of the wing, and are often referred to as "beams."

One method of wing construction is shown in

figure 1-5. In this illustration, two main spars are used with ribs placed at

frequent intervals between the spars to develop the wing contour. This is

called "two-spar" construction. Other variations of wing construction

include "monospar (open spar), multispar (three or more spars), and box

beam." In the box beam construction, the stringers and sparlike sections

are joined together in a box-shaped beam. Then the remainder of the wing is constructed

around the box.

The skin is attached to all the structural

members and carries part of the wing loads and stresses. During flight, the

loads imposed on the wing structure act primarily on the skin. From the skin,

the loads are transmitted to the ribs and then to the spars. The spars support

all distributed loads as well concentrated weights, such as a fuselage, landing

gear, and nacelle. Corrugated sheet aluminum alloy is often used as a

subcovering for wing structures. The Lockheed P-3 Orion wing is an example of

this type of construction. Inspection and access panels are usually provided on

the lower surface of a wing. Drain holes are also placed in the lower surfaces.

Walkways are provided on the areas of the wing where personnel should walk or step.

The substructure is stiffened or reinforced in the vicinity of the walkways to

take such loads. Walkways are usually covered with a nonskid surface. Some

aircraft have no built-in walkways. In these cases removable mats or covers are

used to protect the wing surface. On some aircraft, jacking points are provided

on the underside of each wing. The jacking points may also be used as tiedown

fittings for securing the aircraft.

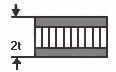

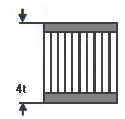

Why sandwitch structure?

The stiffness of a material is dependent upon

its thickness, by making the material thicker, its stiffness is increased. For

example a thick, light beam is needed for load bearing in an aircraft.

Consequently, many composite materials are designed with a thick, light core

sandwiched between two fibre reinforced or prepreg fabric panels.

The table below shows how this design works.

|

|

Solid Laminate |

Sandwich Panel |

Thicker Sandwich |

|

|

|

|

|

|

Stiffness |

1.0 |

7.0 |

37.0 |

|

Flexural Strength |

1.0 |

3.5 |

9.25 |

|

Weight |

1.0 |

1.03 |

1.06 |

By doubling the thickness, the stiffness

increases by x7.

However, in order to maintain the strength of the material, the core must be

able to withstand large forces. This problem is usually overcome by using core structures,

the composite is made up as shown:

|

Pepreg skin |

|

The type of

operation for which an airplane is intended has a very important bearing on the

selection of the shape and design of the wing for that airplane. Planform

determines the stall characteristics of the wing. Angle

of incidence of the wing improves flight visibility, enhances take-off

and landing characteristics and reduces drag in level flight. Wing

washout helps to control the aircraft near its stall angle, the angle

at which the lift coefficient of the wing drops drastically.

PLANFORM

Planform refers to the shape of the wing as seen from directly

above. Wings may be rectangular or elliptical or delta shaped. Some wings taper

from wing root to wing tip, with the taper along the leading edge or along the

trailing edge or, in some cases, with a taper along both edges.

The aspect ratio of a wing is the

relationship between the length or span of the wing and its width or chord. It

is computed by dividing the span by the average chord.

A wing, for example, that has a span of 24

feet and a chord of 6 feet has an aspect ratio of 4. A wing with a span of 36

feet and a chord of 4 feet has an aspect ratio of 9. The actual size, in area,

of both wings is identical (144 sq. ft.) but their flight performance is quite

different because of their differing aspect ratios.

A wing with a high aspect ratio will generate

more lift and less induced drag than a wing with a low aspect ratio.

For this reason, gliders have wings with high

aspect ratios.

ANGLE OF INCIDENCE

The angle of incidence is the angle at

which the wing is permanently inclined to the airplane’s longitudinal axis.

Choosing the right angle of incidence can improve

flight visibility, enhance take-off and landing characteristics and reduce drag

in level flight.

Choosing the right angle of incidence can improve

flight visibility, enhance take-off and landing characteristics and reduce drag

in level flight.

The angle of incidence that is usually chosen

is the angle of attack at which the lift-drag ratio is optimum. In most modern

airplanes, there is a small positive angle of incidence so that the wing has a

slight angle of attack when the airplane is in level cruising flight.

WASHOUT

To reduce the tendency of the wing to stall

suddenly as the stalling angle is approached, designers incorporate in wing

design a feature known as washout. The wing is twisted so that the angle

of incidence at the wing tip is less than that at the root of the wing. As a

result, the wing has better stall characteristics, in that the section towards

the root will stall before the outer section of the wing. The ailerons, located

towards the wing tips, are still effective even though part of the wing has

stalled.

The same improved stall characteristics are

achieved by the device of changing the airfoil shape from the root to the tip.

The manufacturer incorporates a wing shape at the tip, which has the

characteristic of stalling at a slightly higher angle of attack.

Wing construction is basically the same

in all types of aircraft. Most modern aircraft have all metal wings, but many

older aircraft had wood and fabric wings. Ailerons and flaps will be studied

later in this chapter.

To maintain its all-important

aerodynamic shape, a wing must be designed and built to hold its shape even

under extreme stress. Basically, the wing is a framework composed chiefly of

spars, ribs, and (possibly) stringers (see figure 1-5). Spars are the main

members of the wing. They extend lengthwise of the wing (crosswise of the

fuselage). All the load carried by the wing is ultimately taken by the spars.

In flight, the force of the air acts against the skin. From the skin, this

force is transmitted to the ribs and then to the spars.

Most wing structures have two spars, the

front spar and the rear spar. The front spar is found near the leading edge

while the rear spar is about two-thirds the distance to the trailing edge.

Depending on the design of the flight loads, some of the all-metal wings have

as many as five spars. In addition to the main spars, there is a short structural

member which is called an aileron spar.

The ribs are the parts of a wing which

support the covering and provide the airfoil shape. These ribs are called

forming ribs. and their primary purpose is to provide shape. Some may have an

additional purpose of bearing flight stress, and these are called compression

ribs.

The most simple wing structures will be found

on light civilian aircraft. High-stress types of military aircraft will have

the most complex and strongest wing structure.

Three systems are used to determine how wings

are attached to the aircraft fuselage depending on the strength of a wing's

internal structure. The strongest wing structure is the full cantilever which

is attached directly to the fuselage and does not have any type of external,

stress-bearing structures. The semicantilever usually has one, or perhaps two,

supporting wires or struts attached to each wing and the fuselage. The

externally braced wing is typical of the biplane (two wings placed one above

the other) with its struts and flying and landing wires (see figure 1-6).

Wing

Structure subjected loads

|

||||

|

Aircraft Wings are usually subject to two

different types of load:

The wing structure need to be designed to

carry these types of loads Bending

The amount of bending load at any point on

a beam is called the bending moment. Bending

Moment = Force x Distance The bending moment varies along the beam.

The further away from the load a section of

beam is, the stronger it needs to be. In reality, the wing lifting load

distribution is as follows:

So the bending moment distribution looks

like:

The upwards force is trying to push the

beam up. If it isn’t to move, the supporting structure must be supplying a

downwards reaction force.

The upwards force and downwards reaction

will try to make the beam rotate. There must be some other reaction forces

trying to stop the beam rotating. The support exerts a number of small forces

along the beam to prevent rotation.

These forces make the bottom of the beam

increase in length, and the top of the beam decrease in length. This causes

the beam to form a curved shape (a bend).

The part of the beam which does not change

length is called the Neutral Axis. These tension and compression loads are

highest, furthest away from the neutral axis. When designing a structural

beam cross-section we need to keep the material as far as possible away from

the neutral axis, where it will carry no load, and hence be wasted. The

deeper the beam, the greater the bending strength.

Shear

We now have a way of carrying the loads

along the wing. But we still have to carry the up and down loads (known as shear

loads). The shear loads are trying to make the wing adopt a lozenge

shape.

The shear loads are best resisted by carbon

fibres at +/- 45 degrees to the vertical loads, effectively cross bracing the

panel. We can now put all of these elements into a

single structural member. In a wing, this type of beam structure is known as

a spar. A cross-section through a typical spar is shown below.

The F1 wing has two spars to carry the

bending loads.

Torsion

If the bending force applied to an I-beam

does not pass through the center of the beam cross section, the beam will

twist, at the same time as bending.

The point through which a force can be

applied without twist occurring is called the Torsional Centre. For

symmetric beam sections, it is at the centre of the section. For other

sections, it can be some way away from the centre.

The best cross sections to carry torsion

loads have their material as far away as possible from the torsional axis.

The best possible distribution is a circle.

The loads at the centre of a torsional

member are low, so we can save weight by removing the material at the centre,

which isn’t working very hard, and make the cross section hollow.

In conjunction with our wing skins, the

spar webs form three closed sections that we can use to carry our torsional

loads.

The spar webs already have +/- 45 degree

fibres to carry shear loads. We simply have to make the wing skins contain

+/- 45 degree fibres as well.

In the area of the undercarriage, we have a

cut in the lower wing skin. This destroys the torsion carrying capabilities

of one of our cells. We have replaced the single web spars with double web

box spars to get back some of this torsional capability. Wing Skin Buckling

As the tops of our spars stretch and

compress, the wing skins glued to them will have to stretch.

The upper wing skins are in compression in

normal flight and we have to make sure that they don’t buckle. (The lower

skins are in compression in negative ‘g’ manoeuvres.) We can do this in two

ways:

1. Shorten the unsupported length of wing

skin

This is done by breaking the wing into

shorter sections using ribs. These also have the function of maintaining the

wing aerofoil shape in response to the wind loads on it.

2. Increase the bending stiffness of the

skin

This is done by attaching small beams to

the wing skins. These are called stringers. box section beams is

used to add a small amount of torsional resistance to the skins as well.

We can now put the whole wing structure together.

In practice the functions of each of the

components overlap slightly. For example, the wing skins will have some

spanwise carbon in them as well as +/-45, to carry some bending loads, but

the pure split functions described above make it easier to do initial design

work and strength calculations. |

Refrences:

http://composite.about.com/industry/composite/cs/applications/index.htm

http://www.allstar.fiu.edu/aero.html

http://www.aerospaceweb.org/design/ucav/design.shtml

http://www.farnboroughaircraft.com/Aircraft_Design_Theory/Wing_Structure/Wing_Structure.asp